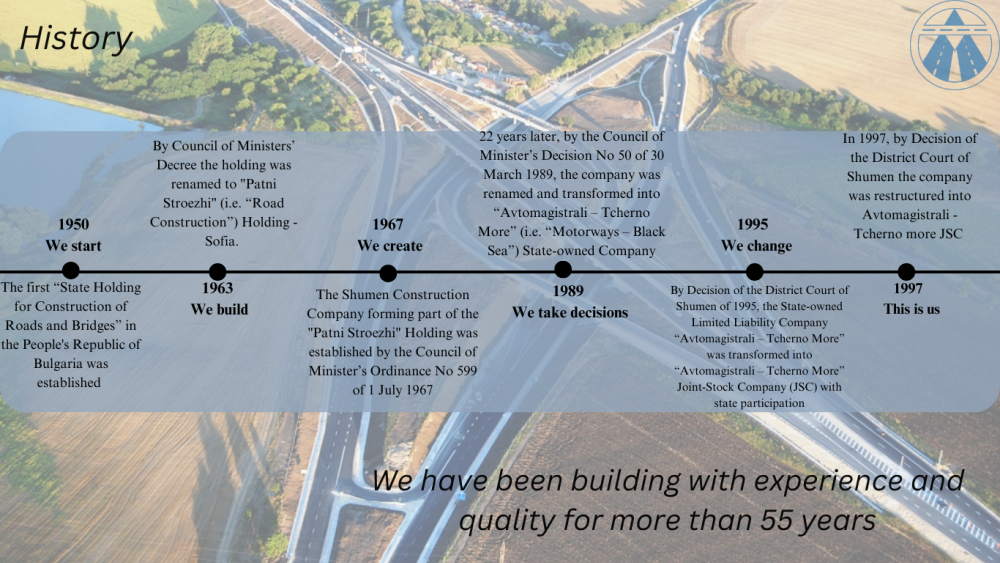

HISTORY

HISTORY

The first “State Holding for Construction of Roads and Bridges” in the People's Republic of Bulgaria was established in 1950. In 1963, by Council of Ministers’ Decree the holding was renamed to "Patni Stroezhi" (i.e. “Road Construction”) Holding - Sofia. Its function was to act as a governmentally supported specialized enterprise intended to perform general road and bridge construction works in Bulgaria. The Shumen Construction Company forming part of the "Patni Stroezhi" Holding was established by the Council of Minister’s Ordinance No 599 of 1 July 1967. 22 years later, by the Council of Minister’s Decision No 50 of 30 March 1989, the company was renamed and transformed into “Avtomagistrali – Tcherno More” (i.e. “Motorways – Black Sea”) State-owned Company, which further changed its legal status to a State-owned Limited Liability Company in 1991. By Decision of the District Court of Shumen of 1995, the State-owned Limited Liability Company “Avtomagistrali – Tcherno More” was transformed into “Avtomagistrali – Tcherno More” Joint-Stock Company (JSC) with state participation. In 1997, by Decision of the District Court of Shumen the company was restructured into Avtomagistrali - Tcherno more JSC.